Uma kukhulunywa ngokukhiqiza izingxenye zepulasitiki, ukukhetha inqubo efanele kubalulekile ukuze kuqinisekiswe ikhwalithi, ukuphumelela kwezindleko, nokusebenza kahle.Izindlela ezimbili ezidumile zokukhiqiza izingxenye zepulasitiki i-urethane casting kanye nokubunjwa komjovo.Kokubili kunezinzuzo nezinhlelo zokusebenza ezihlukile, kepha ukukhetha okungcono kakhulu kwephrojekthi yakho kuncike ezintweni ezahlukahlukene.Kule bhulogi, sizohlola umehluko, izinzuzo, kanye nezimo ezifanele zokusebenzisa i-urethane casting nokubumba umjovo ukuze sikusize wenze isinqumo unolwazi.

Ukuqonda i-Urethane Casting

Ukufakwa kwe-urethanekuyinqubo yokukhiqiza lapho i-polyurethane ewuketshezi ithululelwa esikhunjeni se-silicone ukuze kwakhiwe izingxenye.Le ndlela ilungele ukukhiqiza amanani amancane ezingxenye kanye nama-prototypes ngokuthembeka okuphezulu kanye nemininingwane eyinkimbinkimbi.

Izinzuzo ze-Urethane Casting:

Ingabizi Ngevolumu Ephansi:Ukulingisa nge-urethane kukonga ekukhiqizeni amaqoqo amancane, okwenza kube ukukhetha okuhle kakhulu kuma-prototypes kanye nokugijima kokukhiqiza okufushane.

Isikhathi sokushintsha ngokushesha:Ngokusakazwa kwe-urethane, ukulungiswa kwesikhunta kanye nenqubo yokukhiqiza kuyashesha, okuvumela ukwenziwa kwe-prototyping okusheshayo nokuphindaphinda.

Imininingwane Ephezulu kanye Nekhwalithi Yokuqeda:Ukulingisa nge-urethane kungakhiqiza izingxenye ezinemininingwane eyinkimbinkimbi kanye nokuqedwa okubushelelezi, kulingisa izingxenye zokugcina zokukhiqiza.

I-Material Versatility:Izinhlobonhlobo zezinto ze-urethane ziyatholakala, ezinikeza izici ezihlukene njengokuguquguquka, ubulukhuni, nokuqina.

Izindleko Zamathuluzi Eziphansi:Izibunzi ze-silicone ezisetshenziswa ekubunjweni kwe-urethane zibiza kancane ukukhiqiza uma ziqhathaniswa nezibunjwa zensimbi ezidingekayo ekubunjweni komjovo.

Izicelo Ezikahle Zokusakaza Nge-Urethane:

• Amamodeli we-Prototyping nomqondo

•Izingxenye zangokwezifiso zokukhiqiza ivolumu ephansi

•Ukuhlolwa kwangaphambi kokukhiqiza

• Ukuhlolwa okusebenzayo kwezingxenye ezinamajiyometri ayinkimbinkimbi

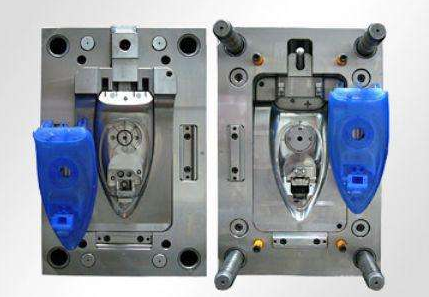

Ukuqonda Ukubumba Umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza lapho ipulasitiki encibilikisiwe ijova esikhunjeni sensimbi ngaphansi kwengcindezi ephezulu ukuze kukhiqizwe izingxenye.Le ndlela iphumelela kakhulu ekukhiqizeni ngobuningi futhi ingakhiqiza izingxenye ezinekhwalithi engaguquki kanye nokunemba okuphezulu.

Izinzuzo Zokubumba Umjovo:

Izindleko Eziphansi Kumavolumu aphezulu:Ngenkathi izindleko zokuqala zamathuluzi ziphezulu, ukubumba umjovo kuba ukonga kakhulu ekusebenzeni okukhulu kokukhiqiza ngenxa yezindleko eziphansi zengxenye ngayinye.

Ukunemba Okuphezulu Nokungaguquguquki:Ukubumba umjovo kunikeza ukuphindaphinda okuhle kakhulu, okuqinisekisa ukuthi ingxenye ngayinye ekhiqizwayo iyafana futhi ihlangabezana nezindinganiso zekhwalithi eziqinile.

Ibanga Elibanzi Lezinto:Uhlu olubanzi lwe-thermoplastics lungasetshenziswa ekubumbeni umjovo, lunikeze izinketho zezingxenye ezidinga izakhiwo ezithile zemishini nokusebenza.

Ukukhiqiza Okuphumelelayo:Ukubunjwa komjovo kungakhiqiza izinkulungwane zezingxenye ngesikhathi esifushane, okuyenza ilungele ukukhiqizwa kwevolumu ephezulu.

Ukuqina Nokuphila Isikhathi Eside:Izibunjwa zensimbi ezisetshenziswa ekubumbeni umjovo zihlala isikhathi eside futhi zingakhiqiza inani eliphezulu lezingxenye ngaphambi kokudinga ukulungiswa noma ukushintshwa.

Izicelo Ezikahle Zokubumba Umjovo:

•Ukukhiqizwa okuphezulu kwevolumu yezingxenye zepulasitiki

•Imikhiqizo yabathengi nezinto zikagesi

•Izingxenye zezimoto

•Imishini yezokwelapha kanye nokupakishwa

•Izingxenye zezimboni nezohwebo

Ukuqhathanisa I-Urethane Casting kanye Nokubunjwa komjovo

Izindleko:

•Ukufakwa kwe-Urethane:Izindleko zokuqala eziphansi kanye nezindleko zamathuluzi;engabizi kakhulu ekukhiqizeni umthamo ophansi.

•Ukubumba komjovo:Izindleko zamathuluzi zokuqala eziphakeme kodwa izindleko zengxenye ngayinye zezindleko ezinkulu zokukhiqiza.

Ivolumu Yokukhiqiza:

•Ukufakwa kwe-Urethane:Ifaneleka kakhulu kumavolumu aphansi kuya aphakathi (izingxenye eziyi-1-1000).

•Ukubumba komjovo:Ilungele ukukhiqizwa kwevolumu ephezulu (izingxenye eziyi-1000+).

Isikhathi esiholayo:

•Ukufakwa kwe-Urethane:Isikhathi sokuhola esisheshayo samaqoqo amancane nama-prototypes.

•Ukubumba komjovo:Isikhathi eside sokuhola ngenxa yokwenziwa kwesikhunta kodwa ukukhiqizwa okusheshayo kwevolumu ephezulu.

Ingxenye Eyinkimbinkimbi Nemininingwane:

•Ukufakwa kwe-Urethane:Kuhle kakhulu kumajiyometri ayinkimbinkimbi nemininingwane emihle.

•Ukubumba komjovo:Iyakwazi ukunemba okuphezulu kodwa ingadinga imiklamo yesikhunta eyinkimbinkimbi futhi ebizayo yezingxenye eziyinkimbinkimbi.

Ukukhetha Inqubo Elungile Yephrojekthi Yakho

Isinqumo phakathi kokukhishwa kwe-urethane nokubunjwa komjovo sincike ezintweni eziningana:

•Ivolumu Yokukhiqiza:Kumavolumu aphansi kuya kokuphakathi, ukukhishwa kwe-urethane kubiza kakhulu.Ngokukhiqizwa kwevolumu ephezulu, ukubumba umjovo kuyisinqumo esingcono.

•Isabelomali:Cabangela izindleko zamathuluzi okuqala kanye nezindleko zengxenye ngayinye.Ukukhipha i-urethane kudinga ukutshalwa kwezimali okuphansi kwangaphambili.

•Isikhathi esiholayo:Uma udinga ukuguqulwa okusheshayo kwama-prototypes noma ukugijima okufushane, ukusakaza kwe-urethane kunikeza izikhathi zokuhola ezisheshayo.

•Ingxenye Eyinkimbinkimbi:I-urethane casting ihamba phambili ekukhiqizeni izingxenye ezinemininingwane eyinkimbinkimbi, kuyilapho ukubumba komjovo kunikeza ukunemba okuphezulu kwenani elikhulu.

•Izinto ezibonakalayo:Linganisa izidingo ezithile zezinto ezibonakalayo zezingxenye zakho bese ukhetha inqubo enikeza izinketho zezinto ezibonakalayo ezihamba phambili.

Isiphetho

Kokubili ukubunjwa kwe-urethane nokubunjwa komjovo kunezinzuzo ezihlukile futhi kulungele izidingo zephrojekthi ehlukene.Ngokuqonda amandla nemikhawulo yenqubo ngayinye, ungenza isinqumo unolwazi esihambisana nezidingo zephrojekthi yakho, isabelomali, nomugqa wesikhathi.Kungakhathaliseki ukuthi udinga ama-prototypes anemininingwane ephezulu noma ukukhiqizwa kwenani elikhulu, ukukhetha indlela yokukhiqiza efanele kuzoqinisekisa impumelelo yephrojekthi yakho.

Isikhathi sokuthumela: Jun-14-2024